Carsem is committed to provide products and services of the highest quality through “ZERO DEFECTS”, preventive Quality culture. Employees will act with honesty, sincerity and operate as a team to continuously strive for improvements in quality, productivity, delivery, services and cost in order to be competitive and profitable. Quality First- It Begins with me.

“ZERO DEFECTS QUALITY is the responsibility of every employee.”

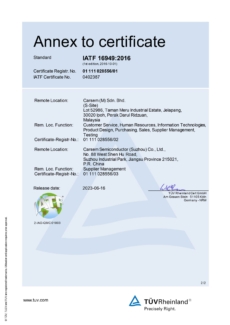

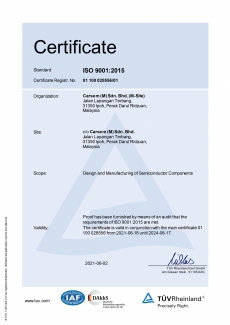

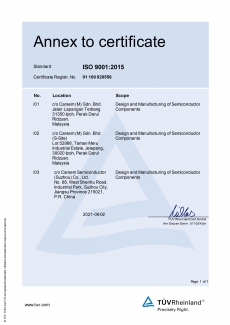

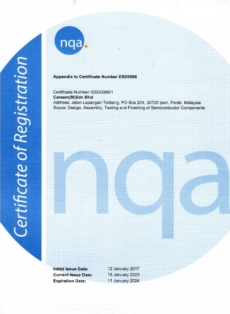

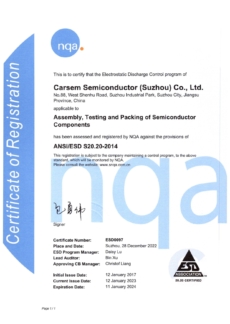

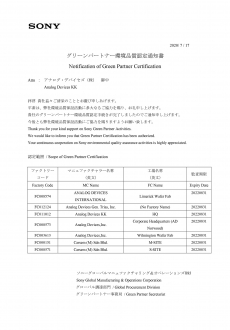

Our factories maintain world-class quality standards having achieved IATF16949, ISO-9001, ISO-14001, ISO45001, ANSI/ESD S20.20 certifications and comply to Sony Green Partner Program.

Our factories maintain world-class quality standards having achieved IATF16949, ISO-9001, ISO-14001, ISO45001, ANSI/ESD S20.20 certifications and comply to Sony Green Partner Program

Our Quality System is based on the following International Standards:

- ISO-9001

- IATF 16949

- ISO-14001

- ISO45001

- ANSI S20 20

Our in-house program called, Continuous Improvement System Towards Zero Defect, consists of:

- Quality ownership – to cultivate Quality First culture

- New Product Introduction Enhancement – to improve the procedure, system and skills involving NPI

- Process Optimization – develop robust processes

- Advanced Process Controls – IT Enabled and Prevention through machine error codes and detection features

- Human Resource Development – emphasize on employee training and skill development

- Supplier Management – Work closely with suppliers to improve on quality CIP

Our factories maintain world-class quality standards having achieved IATF16949, ISO-9001, ISO-14001, ISO45001, ANSI/ESD S20.20 certifications and comply to Sony Green Partner Program

| Floor Area | M Site 436,000 sq. ft. |

S Site 640,000 sq. ft. |

Suzhou 600,000 sq. ft. |

|---|---|---|---|

| Cleanrooms | Class 10k Frontline Assembly | ||

| Class 100k Backend Assembly | |||

| Temperature, RH, Particle Count and ESD-Controlled | |||

| Production Support | 24-hour Security Surveillance | ||

| Internal Calibration Laboratory | |||

| Centralized Air-Conditioning | |||

| Cold Storage | |||

| Communication System (Tel/Fax/Email) | |||

| DI Water System | |||

| Emergency Power Generators | |||

| IIMEC (Integrated Information for Manufacturing Excellence at Carsem) | |||

| Failure Analysis/Reliability Laboratory | |||

| Fire Protection and Alarm System | |||

| Liquid and Gas Nitrogen | |||

| Oil-Free Air Compressors | |||

| Tool and Die Machine Shop | |||

| Waste Treatment Plant | |||

| Operation | Two 12 hour Shifts for 24 hour Operation | ||

- Autoclave-JEDEC A102

- Board Level Temperature Cycling for Solder Joint Integrity Check

- HAST / UHAST

- High Temperature Storage – JEDEC A103

- Convection reflow

- Temperature/Humidity Chamber for Moisture Sensitivity Testing

- Thermal Shock Chamber (LIQUID) – MIL-STD-1011 – (Available in M-Site and S-Site ONLY)

- Temperature Cycle Chamber (AIR) – MIL-STD-883,1010 / AEC-Q100

- Grinder/Polisher/Low Speed Saw

- Laser decapsulation system

- Micro probing Station – (Available in M-Site and S-Site ONLY)

- Metallurgical Microscopes

- Scanning Electron Microscope & EDX

- Scanning Acoustic Microscope

- Stereomicroscope/High Power Microscope

- X Ray

- Ion miller