CARSEM CTC to be recognized as the preferred partner for semiconductor subcontracting & the ideal place to work for the best engineering talent in this region.

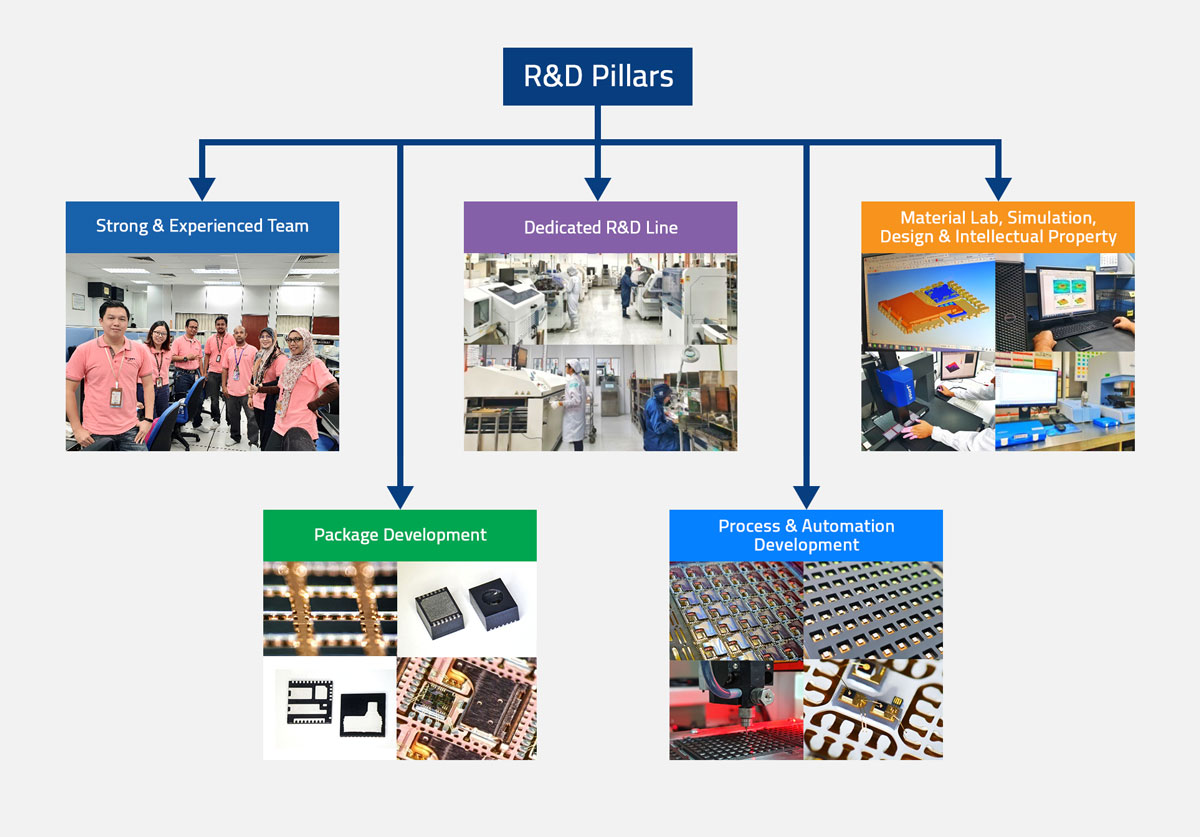

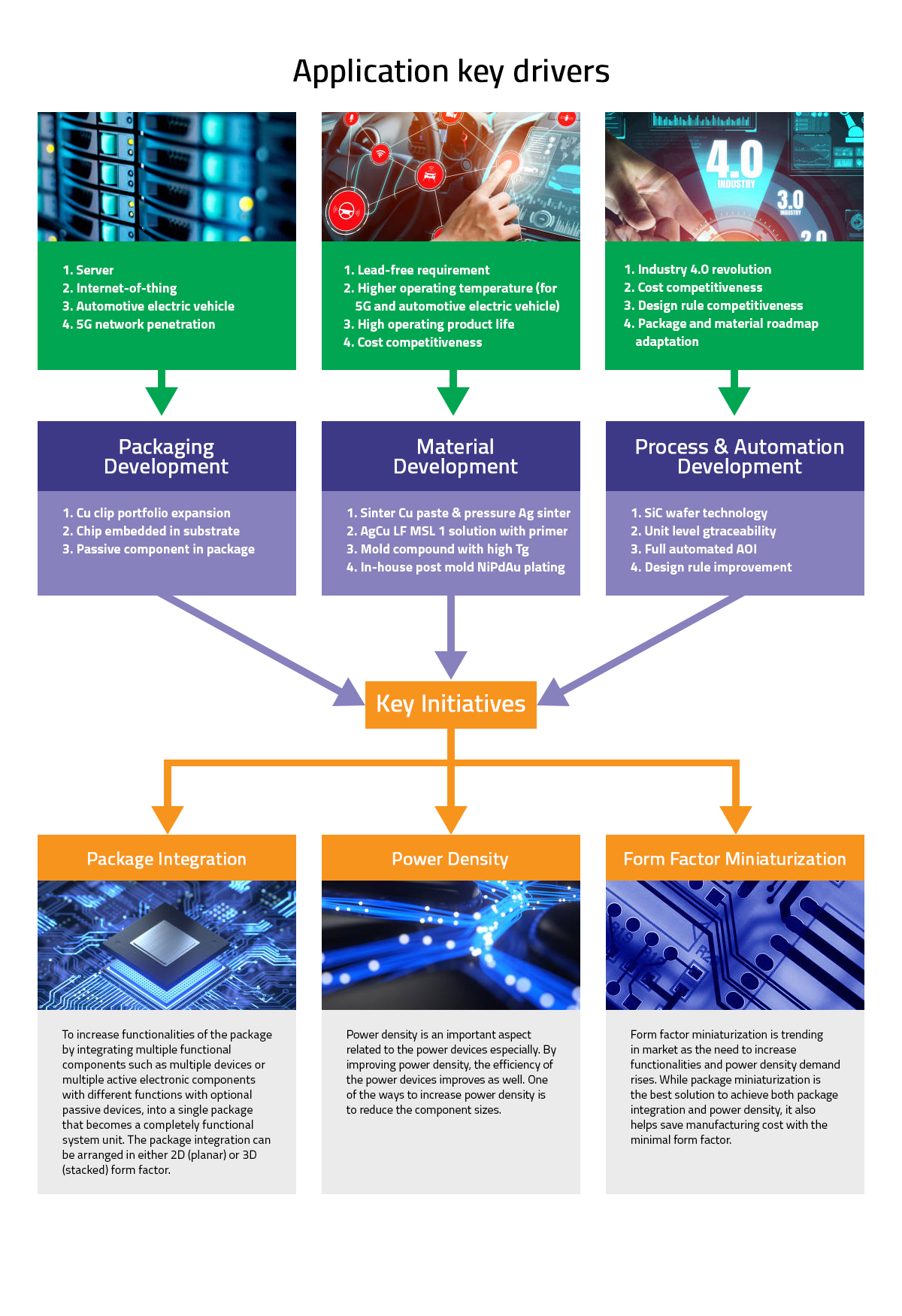

To explore new frontiers, develop technologies & competencies in line with customer needs that would provide CARSEM a competitive edge in increasing revenue & profitability.

- To ensure that Carsem’s technology roadmap aligns with or is as close as possible to our key customers

- To minimize time to market through efficient process, planning & resourcing of R&D Projects

- To keep customers updated on R&D progress while ensuring that we extract maximum commercial value from our R&D programs

- To identify packages and technology opportunities that are new & innovative, and may not be on Carsem’s existing roadmap