Carsem is a global leader in MEMS & Sensors advanced packaging & test and is among the world’s leaders in microelectronics packaging.

Carsem has a dedicated MEMS & Sensors Business Unit (MSU) which drives focused investments in this area. MSU boasts of “advanced design, development & prototyping capabilities” to accelerate MEMS products towards mass manufacturing. By virtue of a strong automotive MEMS sensor portfolio, MSU’s emphasis on Quality continues to inspire customer’s confidence in its capabilities to launch new sensor packages in a variety of applications including Industrial, IoT, and Consumer segments.

Our dedicated and experienced MEMS Team can provide comprehensive turn-key solutions that begins with package co-design, thermal/stress simulations, engineered BOM selection for reliability, qualification support and in-house test development.

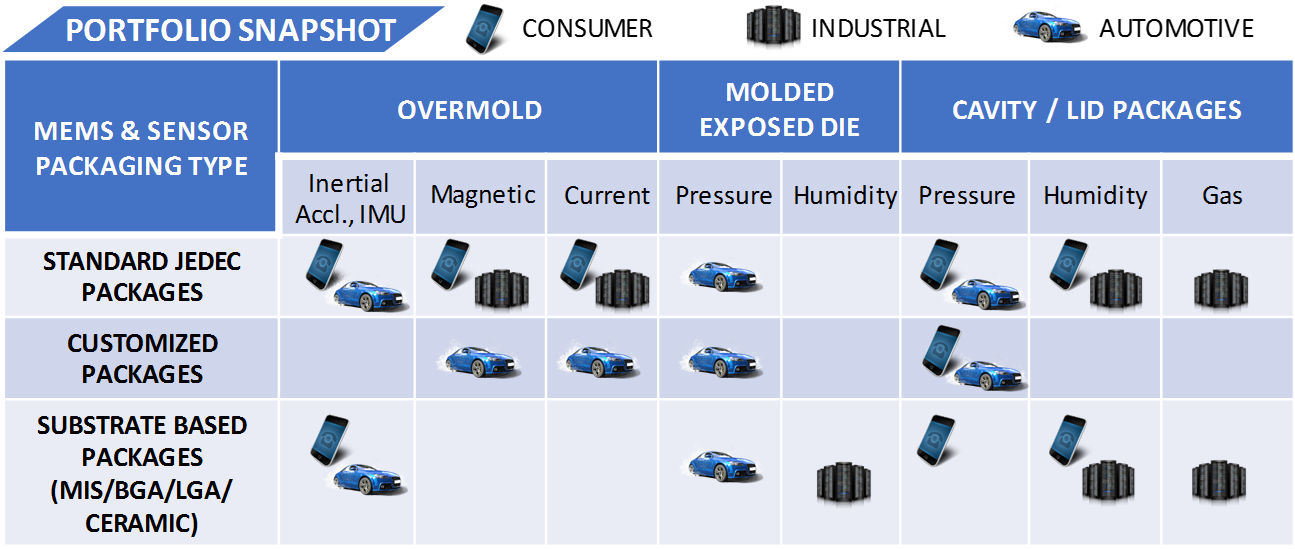

ENVIRONMENTAL HUB MEMS SENSORS PACKAGE OVERVIEW

- Custom Molded Cavity Packages

- Lid packages with metal and plastics (LCP)

- Laminate and lead-frame base packages

INERTIAL HUB MEMS SENSORS PACKAGE OVERVIEW

- SOIC family

- QFN / DFN & Micro Leadframe Packages (MLP)

- LGA (LF, MIS) and Custom Packages

MAGNETIC & CURRENT HUB MEMS SENSORS PACKAGE OVERVIEW

- SOIC family

- LGA (MIS) and Custom Packages

EXPERIENCED MEMS STAFF

- A Fully Dedicated MEMS Staff

- History of Launching Difficult MEMS Sensors

DEDICATED MEMS MANUFACTURING LINES

- Dedicated MEMS Manufacturing Line

- IATF 16949, ISO-9001, ISO-14001, ANSI/ESD

- Investment in the latest Equipment

- State-of-the-Art Industry 4.0 Assembly

- Manufacturing Excellence System (MES)

- Complete traceability and data analytics

ADVANCED CORE TECHNOLOGY & TOOLBOX

- Cutting Edge MEMS Packaging Roadmap

- Advanced Electronics Materials Roadmap

- Advanced MEMS Wafer & Die Preparation

- Advanced MEMS Die Bond & Wirebonding

- Advanced Molding Technology for MEMS

- System in Package (SiP) Technology

- Flip Chip and CuPillar Technology

- Molded Interconnect Substrates (MIS)

SIMULATION, ANALYSIS, AND DESIGN OPTIMIZATION

- Thermal-Mechanical Simulation

- Electrical Simulations

- RF Simulation

- Mold Flow Simulation

- For Package & Board Level Reliability

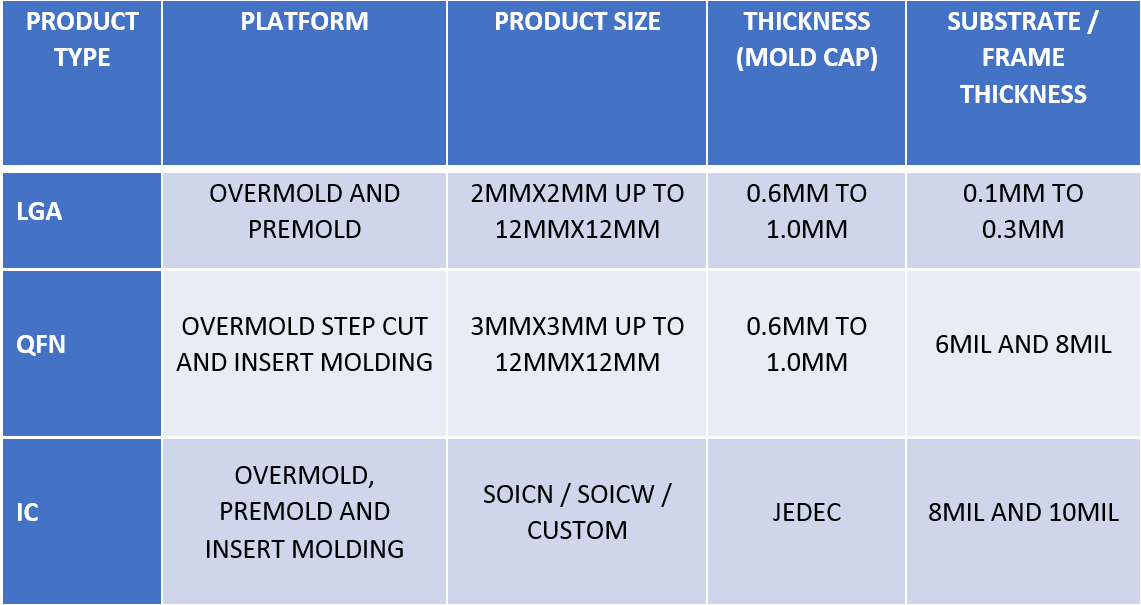

- 1) Packages : LGA / MIS from 2mmx2mm to 10mmx10mm

- Mold cap: 0.52mm – 1.2mm

- Substrate thickness: 120um – 320um

- Capability integration with SMT from 0201, 0402 and 0603

2) Packages : MLP from 2mmx2mm to 10mmx10mm

- Mold cap: 0.52mm – 1.2mm

- Lead frame thickness: 150um to 200um

3) Customized Cavity package and Over mold packages on substrate and lead frame

The packages performance depends on customer requirements from MSL, MSL2 , MSL 3 to Automotive Grade 0 to 3.