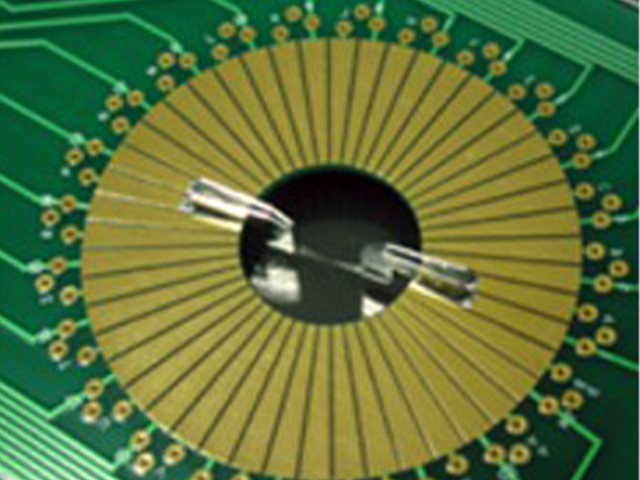

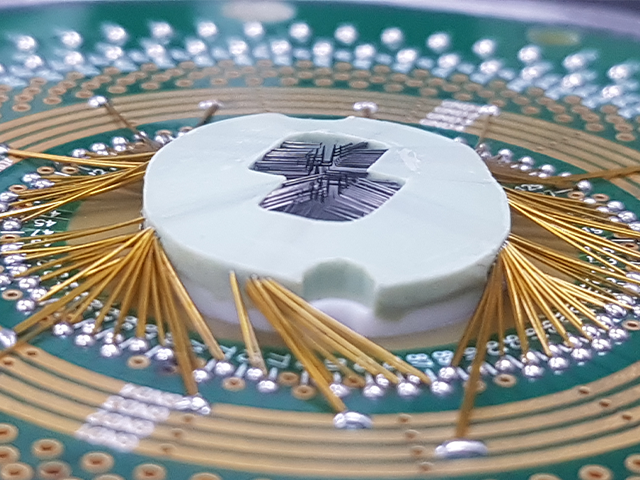

Wafer Probing is a step performed during semiconductor device fabrication. During probing step all individual circuits that are present on the wafer are tested for functional defects by applying special test coding to them. By doing wafer probing the company can save assembly and final test costs by rejecting the non-functional dies in the wafer. The wafer probing is performed using test equipment called a wafer prober.

Carsem Wafer Probe Business Unit offers:

- Wafer size – Able to support probing from 100mm up to 300mm for both bumped and normal wafer

- Wafer thickness – Able to support down to 4mil thin wafer probing

- One-stop from design to HVM (high volume manufacturing)

- Provide high multisites testing solution – conversion from single to multisites

- Various type of probing interface solution – performance & cost

- Multiple Tester platform – Eagle, Teradyne, TMT, Fusion, Amida

- Prober – Electroglass, TEL, TSK

- Wafer Electronics Mapping & Inking

- Able to do full probe, sample probe & smart probe

- Support -55⁰c to 150⁰c probing

- 25+ years of wafer probe experience

Up to 1 sites

Up to 16 sites

Up to 16 sites

Strip testing is a testing process for semiconductor devices while it still remain in lead frame strip form. The devices in lead frame strip form had first gone through the sawing process for electrical isolation of the device leads. The process flow is as below:-

- Strip Mounting

- Saw Singulation

- Strip Testing

- UV Cure

- Pick and Place & Tape and Reel

- Final Visual

- Packing

- Ship

- Max UPH 15k (1s test time@8sites)

- High parallelism (up to 64 sites)

- Auto contractor alignment and cleaning

- No package conversion kit required

- Fast setup time (<20mins)

- MTBA >2 hrs

Final testing is a testing process for semiconductor devices while it had been singulated as individual pieces. The singulated units will undergo a series of testing performed by the tester to confirm the device functionality, electrical performance, and in some sophisticated devices, it will also write data into device memory. A test handler is used to carry the singulated units to test in designated environment or temperature, and sort the complete tested device according to the result.

Integrated Testing

- Testing and tape & reel performed on single equipment

Non Integrated Testing

- Testing and tape & reel handled by 2 equipment

Burn-in Testing

- Burn-in oven

Post Test Services offered the customers with the variety on how the tested good parts to be packed and delivered to their end customers.

- Sound knowledge of material and sealing technique

- Strong process and equipment engineering background

- Define & design Tape and Reel equipment buy off criteria

- SPC widely applied

- Materials evaluation and development experience

- Strong manufacturing background