Semiconductor Test is playing a critical role in the manufacturing process to ensure parts delivered to customer to be defect-free. It needs to ensure that no devices that have been damaged along the packing processes being escaped to the field. Only good device that pass the final test will be proceed to be sealed and packed as per commercial goods ready for sale. As the product designs become more heterogeneous, number of tests required is growing and it turn test to be a portfolio of separate operation.

As a leading provider of turnkey packaging & test services to the semiconductor industry, Carsem offering one of the largest packages & test portfolio in the world for last 45 years. Test is facilitated at 2 plants – Ipoh (S-Site), Malaysia and Suzhou, China.

With a vast range of equipments as well as a strong and dedicated operations team, Carsem provides a full range of test services to meet the unique needs of our customers’ device requirements. We emphasize on the continuous improvements on all aspects to provide advanced technology, quality, performance and cost of test.

- Floor space: 10,500 square feet, 9,755 square meter

- Workforce: 1,018 employees

- Equipment: 522 Handlers, 575 Testers, 103 Probers, 60 Tape & Reel Equipment, 91 Others

- Floor space: 4460 square meter (Suzhou)

- Workforce: 471 employees

- Equipment: 221 Handlers, 135 Testers, 19 Tape & Reel Equipment

- Consigned: 20 Handlers, 178 Testers

- Production Commenced in 2004

- Floor space: 10,500 square feet, 9,755 square meter

- Workforce: 1,018 employees

- Equipment: 522 Handlers, 575 Testers, 103 Probers, 60 Tape & Reel Equipment, 91 Others

- Floor space: 4460 square meter (Suzhou)

- Workforce: 471 employees

- Equipment: 221 Handlers, 135 Testers, 19 Tape & Reel Equipment

- Consigned: 20 Handlers, 178 Testers

- Production Commenced in 2004

- Static Dissipative Flooring

- Conductive Shoes

- In-handler Ionizers

- Grounded Work Stations

- Temperature : 23 +/- 4°C

- Humidity : 50 +/- 10%

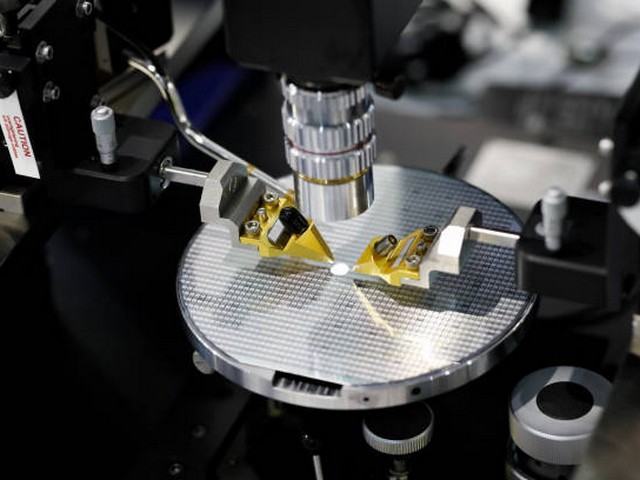

Carsem Test Team with extensive experience and capability is ready to provide a full range of test services, covering both the “front-end” process through wafer probing, as well as the “back-end” process, which includes final testing on assembled device.

As a Test solution partner, we offered services which includes:

- Test consultation & development services for both new products and platform migration

- Wafer Probing services

- Final testing from simplest open/short test on singulated units to advanced package testing with fully automated machine, high parallelism testing, strip testing, burn in, reliability testing & etc.

- A full suite of optimized post-test services including tape-and-reel, baking, pack & labelling, drop-ship service with short cycle time & rapid delivery of the final products to the end customer

Carsem is focused on turn-key services and thus has a total dedicated test and wafer probe area of 125,000 sq ft (11,700 sq m) containing over 500 testers and handlers. Carsem provides a full range of test services to meet the unique needs of our customer’s device requirements including RF, mixed signal and power applications and currently test over 60% of the total units we assemble.

Carsem maintains a dynamic tester and handler technology roadmap to align our investments to our customer’s needs and has a core dedicated staff of product, process and test engineers capable of developing custom solutions from scratch to address any specific device requirements. These solutions include program/hardware development services, program conversions, as well as, complete product engineering support including program debug, correlation, low yield analysis and test time reduction.

We have the ability to test devices for Bluetooth, WLAN, 802.11a/b/n/ac and a wide variety of other applications using test systems that include the LTX Fusion CX RF, Rack and Stack and Teradyne Catalyst/RF. Additional tester platforms for mixed signal, analog and power management devices include the TMT/ASL, Eagle, and Teradyne Microflex. Carsem is also familiar with a line of low cost mixed signal/analog testers such as Chroma, Amida, Powertech and Aemulus. Carsem provides both wafer probe services for wafers up to 8″ in diameter (including hot chuck and wafer mapping features) and strip test for various MLP package dimensions (including packages sizes below 2×2 mm) . Other turn-key services include dry pack, tape and reel, finished goods inventory, bar code and drop shipment.