Carsem R&D focusses to formulate and implement strategies for new packages, assembly technology and materials to enhance manufacturing capability. Our efforts in development create value & differentiation through packaging design / process technology / custom solution.

With dedicated floor space of 14,000 sq.ft, Carsem Technology Center (CTC) has 103 dedicated staff comprising of Engineers, Technical Management and 24×7 support staff.

Our dedicated R&D Pilot Line is well equipped to formulate and implement strategies for new packages, assembly process technology and materials to enhance manufacturing capability.

CTC strive on innovating and expanding package technology portfolio in line with corporate strategy to be leading OSAT in 4 sectors such as:

- MEMS & Sensor

- RF

- Automotive

- Power Packaging

The CTC Material Lab act as knowledge base for R&D activities and a service provider for our customers and production assembly.

The service we provided includes:

- Failure Analysis

- Thermal Material Analysis

- Mechanical Testing

- Reliability Testing

- Assembly Service Testing

- Failure Analysis

- Thermal Material Analysis

- Mechanical Testing

- Reliability Testing

- Assembly Service Testing

There are total of 16 equipments and over 24 testing services available.

Simulation Lab are capable of modeling and predicting Stress, Thermal and Electrical behavior of the electronic packages. By simulating and predicting the Stress, Thermal and Electrical behavior, we are able to understand the impact of different designs on the electronic packages.

Design Lab capability includes providing design service for electronic package by following the specification best suited for the package or requested by our customers.

Here in CTC, we establish, implement and improve the process capability suitable with the industrial needs and meets the specification as requested by our customers.

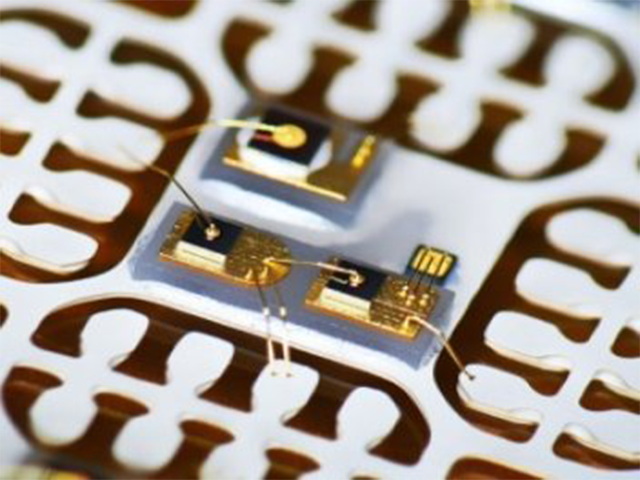

As a >20 years preferred certified automotive supplier, CTC has proven the capability in process development of MEMS & Sensor, RF for Connectivity and 5G Assembly & Testing such as:

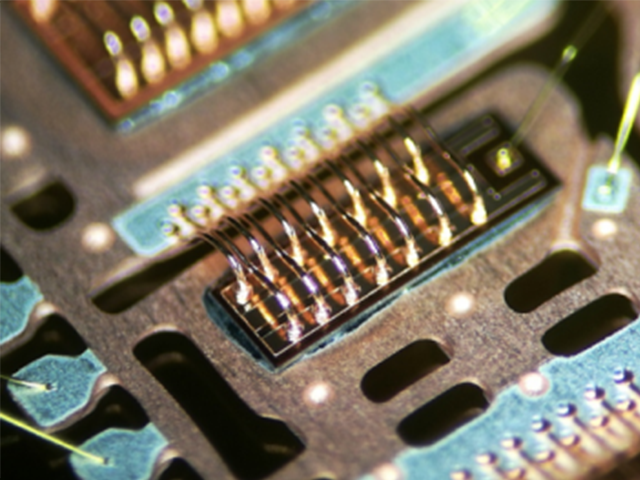

- Copper / Gold Wire Bonding

- Copper Clip Attach

- Film Assisted Molding for Cavity package

- Flip Chip

- Stacked Die

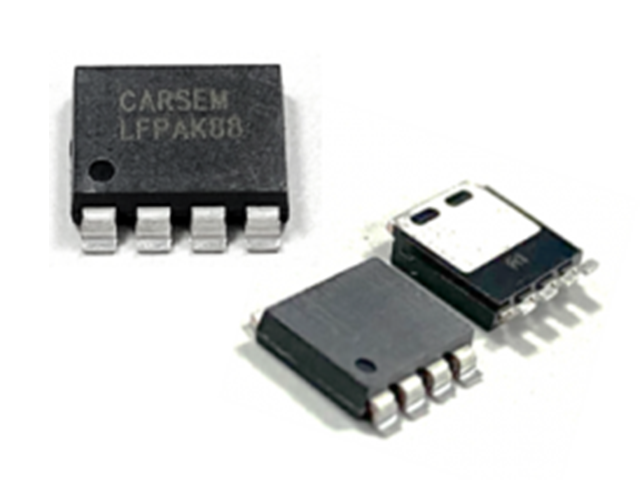

Carsem have the experience of >30 years in power packaging. CTC played a big role in package development in order to ensure our package is build in the best condition.

Our electronic package includes:

- TVS

- SOIC

- MICRO

- Flip Chip on Lead

- QFP

- LGA (Leadframe / Substrate)

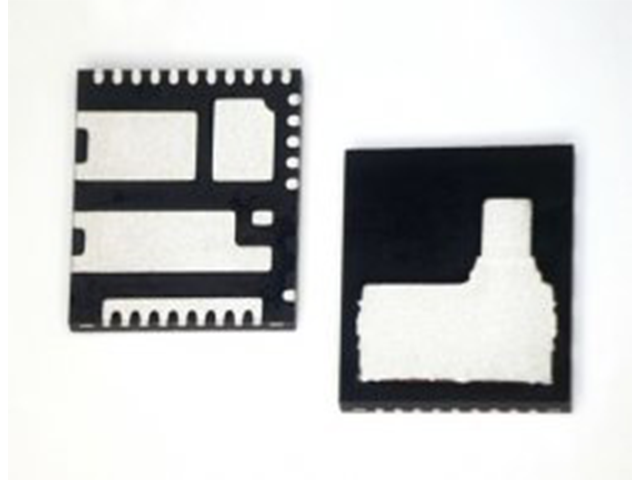

- MLP: Flip Chip, SiP, MCM

- Copper Clip Packages: Exposed Clip, Non-Exposed Clip

- Power Module (Dev)

- LFPak (Dev)

- TO Packages

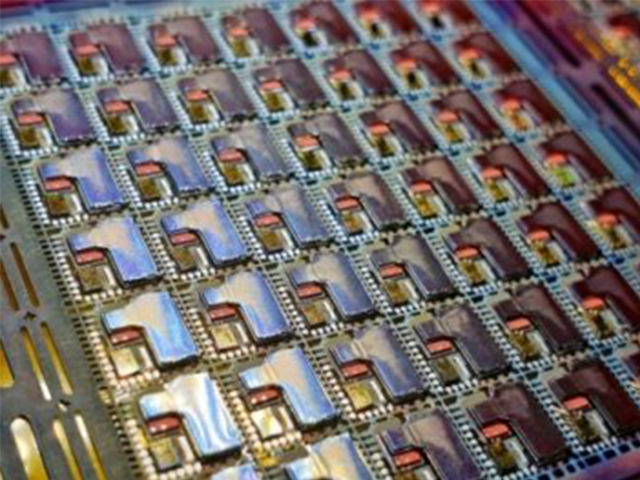

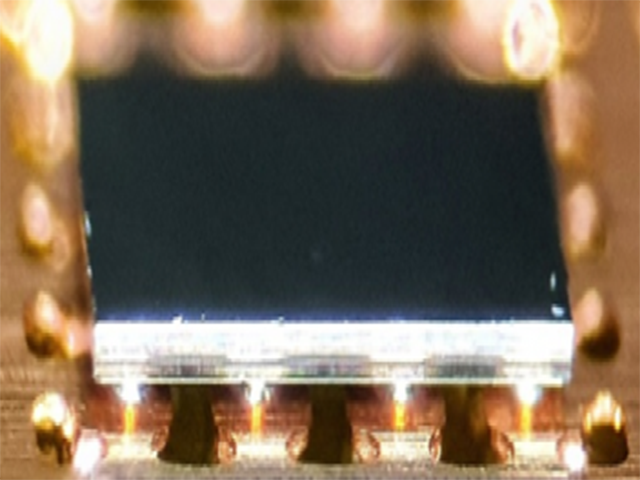

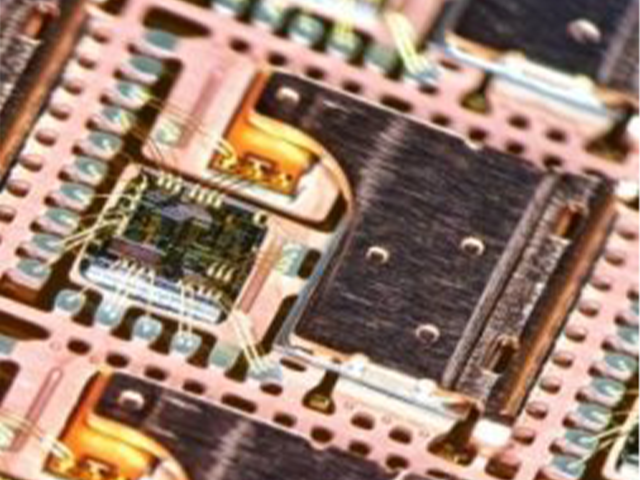

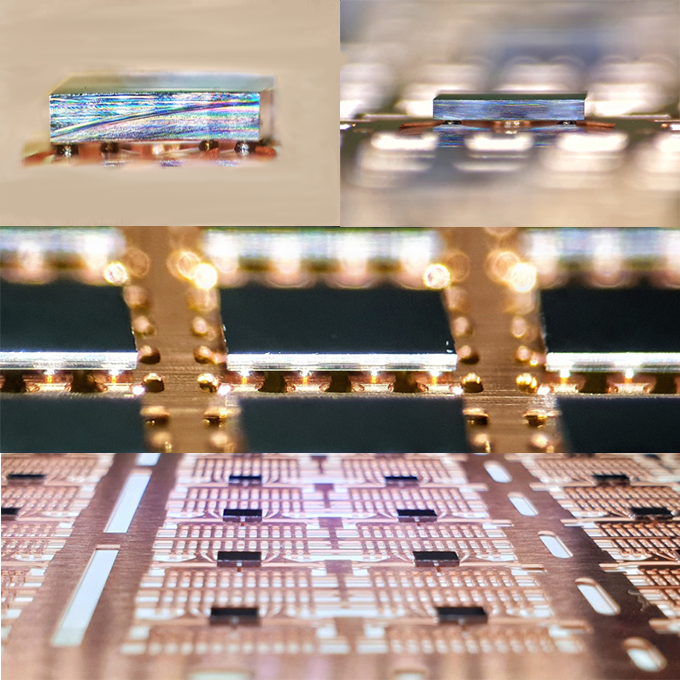

Cavity packages since the year of 2005 using premolded Cavity package on leadframe. We have since refined this capability to open cavity on-die utilizing Film Assist Molding technology. This cavity on-die capability enables our customer to shrink their package sizes by half. Cavity packages are widely used in MEMS for leaded and leadless package mainly in automotive.

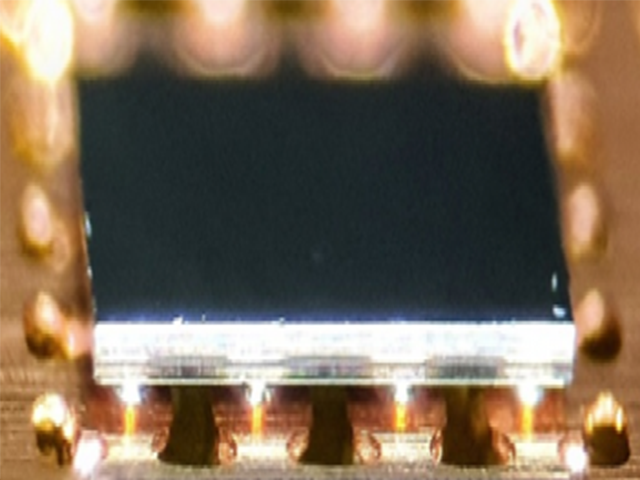

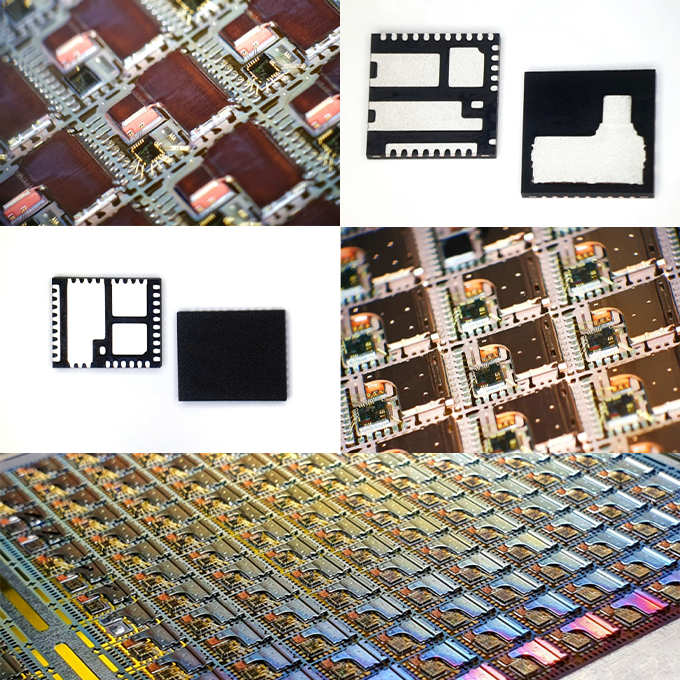

Carsem is experienced with copper clip development for more than 15 years. It first started with the single clip design and then has now expanded into variety of design ie exposed copper clip (developed to increase the heat dissipation), single clip-multi die, stacked clip, die on top of clip and the likes.